Water quality meets global emission standards

suzhou industrial park yinghan power auxiliary machine co., ltd,is a professional manufacturer specialized in the research, design and manufacturing of high-efficiency fiber filter series water treatment fiber filter. our leading product is the pore controllable fiber filter authorized by the national patent, also known as TWF pore controll fiber filter. Since its establishment, the company has been committed in this field, mastered the core technology of PCF pore controll fiber filter, The company has formed the design and production capacity of a complete series of water treatment fiber filtration equipment with twisting PCF pore controllable fiber filter as the leading product and the other two series of fiber filtration equipment as the auxiliary. Through cooperation with numerous engineering companies, the company's leading product PCF pore controll fiber filter has been successively obtained in some engineering projects at home and abroad, which has solved the user's practical problems and has been favorably received by the user.

PCF pore controllable fibre filters are currently the most advanced fibre filter. It has a flow rate of 80 to 100m/h, with a large flow, small footprint, high filtration precision, and easy to achieve automation.

In addition, the SQZ series of water sampling equipment produced by our company for the steam and water sampling analysis of the industrial boiler also has wide application in the fields of electric power, metallurgy and petrochemical industry.

Company factory covers an area of 10000 square meters, construction area of 5000 square meters, the main equipment are: plasma cutting machine, profile cutting machine, double cutting torch cutting machine, automatic cutting machine, shearing machine, roll machine, bending machine, all kinds of cutting machine tools, all kinds of lifting equipment, hydraulic press, pipe bender, air compressor, pressing machine, spot welding machine, silicon controlled rectifier welding machine, automatic welding, ultrasonic thickness gauge, X-ray thickness gauge, ultrasonic flaw detector and transistor, etc.

The company's development purpose is: dedicated, professional, cooperation and win-win. In the future, the company will continue to adhere to the principle of "user first, quality first", continue to do its own main business, and work well with the engineering company and relevant users to work hard to improve the water environment of the earth.

|

Pore Controllable Fiber Bundle Filter, also can be referred to as TWISTING FIBER FILTER. The water filtration equipment which using a specially treated long fiber as the filtration medium. In view of the disadvantage of relatively small filtration area of traditional fiber filtration equipment, this equipment adopts the transverse flow filtration mode, which effectively increases the filtration area and increases the flow rate of the equipment without increasing the diameter of the equipment. In 1990s, the concept of twisting fiber filter was firstly put forward and implemented in China. On the basis of summarizing and improving previous technologies, our company has applied for relevant patents and obtained authorization.

|

Twisting pore controll fiber filter is an advanced filter equipment. It USES a kind of stable performance, high strength single filament soft, high strength curved fiber filament as the filter material, with the electronic control system, to achieve the filtering of raw water treatment, which has the advantages of high filtering accuracy, large flow, relatively small cover area.

Different from the traditional longitudinal flow filtration method, the incoming-water is transversely through the filtration layer, so with the same diameter the equipment can achieve a larger flow velocity and flow rate.

|

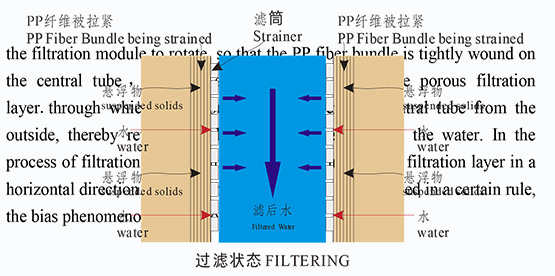

As shown in the figure on the right, the rotating units outside the tank drives the filtration module to rotate, so that the PP fiber bundle is tightly wound on the central tube,forming a uniform, tiny and dense porous filtration layer.through which the incoming water enters the central tube from the outside, thereby retaining and adsorbing the sewage in the water. In the process of filtration, the incoming water goes through the filtration layer in a horizontal direction. Because the PP filter wires are arranged in a certain rule, the bias phenomenon will not occur.

|

|

A certain number of fine PP fiber bundles are longitudinally wrapped on the central gathering pipe to form a filter unit. One or four sets of filter units are set in the tank according to the size of the filter specifications.

The surface area of the four filter cartridge in the equipment is larger than the cross-sectional area of the tank, so its theoretical filtration rate can be up to 100m/h. Generally, it can reach 60 ~ 80m/h. For example, the flow rate of DN2000 torsional pore regulated fiber filter can reach 200 ~ 300T/H, while the conventional flow rate of DN2000 high efficiency fiber filter is 30m/ H, and the corresponding flow rate is 94T/H.

|

|

|

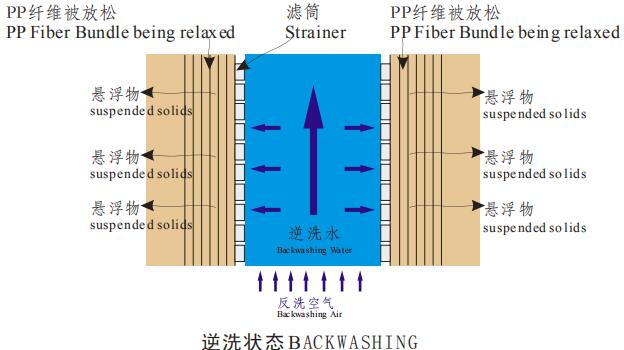

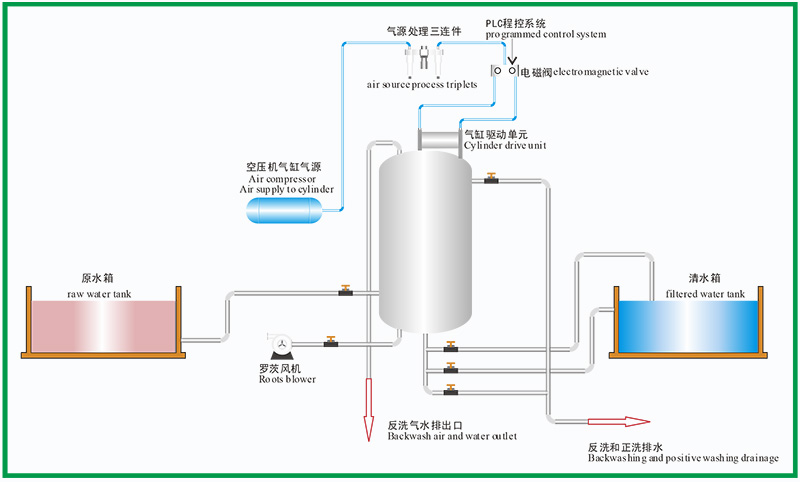

The compressed clean air, make PP fiber bundle in the process of cleaning produce strong jitter and rubbing against each other, and Plus the carrying effect of cleaning air,the sewage intercepted on the fiberbundle can be easily peeled off by the combined washing water and cleaning air. In addition, the rotary mechanism drives the filter wire to repeat several times of rotation and relaxation during the backwashing process, which is helpful to obtain better backwashing effect similar to that of washing machine.

High strain rate:The filtration speed is up to 60 ~ 80m/h, and the maximum is up to 100m/h. The diameter of the twist pore control fiber filter equipment with a single processing capacity of 300m3/h is DN2000MM;

Rapid backwashing:The reverse washing process can be completed in 3 ~ 5min.

High quality filter material:High quality PP fiber bundle filter material is adopted, which has good chemical stability, acid resistance, alkali resistance, oxidant resistance and biodegradation resistance, and has good adaptability to water quality changes of raw water.

Low water consumption:Because of the good backwashing effect, the backwashing process can be completed in a relatively short time, the self-use rate of reverse washing is 1 ~ 3% of the periodic water yield.

Low one-time investment:With the same processing capacity, the area is only 1/3 ~ 1/2 of the traditional filter.

Low pressure differential filtration, low energy consumption:Water head loss at the end of filtration is less than or equal to 0.08Mpa.

Easy to maintain:The filter material has a long service life, and easy to replace.

with high level automation,Fully automatic operation can be realized.

high efficiency and excellent water quality: The filtration accuracy can reach 2 ~ 5μm, and the removal rate of suspended solids can reach more than 95%.

Compared with other types of filtration equipment, the twisting pore control fiber bundle filter has many advantages, such as high filtration efficiency, small volume, light weight and low price (according to the unit volume of water). The following table lists the comparison of technical indexes of TWF pore regulating fiber filter, mechanical filter and high-efficiency fiber filter (for reference only).

|

對比項目items |

機械過濾器 |

高效纖維過濾器 |

扭轉式孔隙調節型纖維過濾器 |

|

過濾方式 filter type |

表面過濾 |

深層過濾 depth filtration |

深層過濾 |

|

過濾速度(m/h) Filtration velocity |

8~10 |

20~40 |

60~100 |

|

濾材種類 Filter material types |

砂石 |

丙綸纖維 |

柔性曲化,高強度纖維絲束 |

|

濾材更換 Filter material replacement |

不便 inconvenience |

不便 inconvenience |

便于更換 |

1. Quality Water

For: production of tap water, drinking water, pure water, high pure water, industrial water

Process: A. Raw water (low turbidity water: concentration less than 100 mg/l) →micro-flocculation→ TWF filter →post-treatment→ effluent

B. Raw water (high turbidity water: concentration >100 mg/l) → coagulation clarification →TWF filter→ post-treatment →effluent

For: swimming pool water treatment, aquarium water circulation, water park, artificial landscape, freshwater aquaculture

Process: raw water→ hair collector→ microflocculation →PCF filter →recycling.

3.Reuse Of Reclaimed Water

For: miscellaneous water reuse, hotel water treatment, accommodation area water treatment

Process: to be treated water→grille→clarification precipitation→contact oxidation→microflocculation→PCF filter→disinfection→reuse

4.Sewage In--Depth Processing

Used for: direct treatment of effluent after physicochemical/biochemical treatment of domestic sewage or industrial wastewater.

Process: wastewater→primary sedimentation tank→biochemical treatment→coagulation precipitation→PCF filter→ reuse

Concrete application

1.Prefiltration of softening water system

replace the traditional sand filter, prevent the impurities in water such as suspended matter and colloid from entering into the resin layer to wrap and contaminate the resin, reduce its exchange function, and ensure the periodic water production and regeneration effect of the ion exchange resin.

2.Circulating water treatment for condenser in power plant

It is used to remove the rust, suspended matter and colloidal metal corrosion products in the circulating water, prevent these tiny suspended matter and colloidal particles from entering the condensate water desalting system, and affect the exchange capacity and working cycle of the resin.

3.Chemical pretreatment of membrane water treatment system

Interception of sediment, clay, suspended matter and other small particles in water, to prevent impurities into ultrafiltration, reverse osmosis and other membrane elements, blocking the filter channel, causing mechanical fouling. The cleaning cycle and service life of the film can be prolonged.

4.Circulating water filtration in steel industry

Filter a large amount of rust, iron slag, biological slime, algae, microorganisms and other corrosion products in the circulating water to prevent pipe and nozzle blockage.

5.Oil field return water injection filtration

The groundwater resources shall be protected from contamination by removing suspension, macromolecular bacteria, organic matter and some fine particulate impurities back into the water injection.

|

型號 model number |

流量(m3/h) produced water quantity |

參考外形尺寸(Φ×H:mm) reference dimension |

|

PCF75 |

75 |

Φ1200×3800 |

|

PCF100 |

100 |

Φ1500×3800 |

|

PCF120 |

120 |

Φ1500×4200 |

|

PCF150 |

150 |

Φ2000×4000/Φ1800×4400 |

|

PCF200 |

200 |

Φ2000×4700 |

|

PCF250 |

250 |

Φ2200×5100/Φ2000×5300 |

|

PCF300 |

300 |

Φ2200×5550/Φ2000×5750 |

|

PCF350 |

350 |

Φ2400×5350/Φ2200×5850 |

|

PCF400 |

400 |

Φ2400×5700 |

|

PCF450 |

450 |

Φ2400×6200/Φ2800×5600 |

|

PCF500 |

500 |

Φ2800×6500 |

|

注:表中設備規格僅供參考,具體應以雙方簽字的設計圖紙為準。 Note: the equipment specifications in the table are for reference only, and shall be subject to the design drawing signed by both parties. |

||

|

型號 model number |

流量(m3/h) produced water quantity |

參考外形尺寸(Φ×H:mm) reference dimension |

|

PCF5 |

5 |

Φ380×1500 |

|

PCF10 |

10 |

Φ400×1750 |

|

PCF15 |

15 |

Φ480×1700 |

|

PCF20 |

20 |

Φ550×1850 |

|

PCF25 |

25 |

Φ550×2200 |

|

PCF30 |

30 |

Φ650×2500 |

|

PCF40 |

40 |

Φ800×2500 |

|

PCF50 |

50 |

Φ900×2700 |

|

PCF60 |

60 |

Φ1000×2800 |

|

注:表中設備規格僅供參考,具體應以雙方簽字的設計圖紙為準。 Note: the equipment specifications in the table are for reference only, and shall be subject to the design drawing signed by both parties. |

||

|

設計壓力 Design Pressure |

0.6Mpa |

工作溫度 Working Temperature |

5~60℃ |

|

工作壓力 Working Pressure |

0.55Mpa |

反洗周期 Cycle Of Backwashing |

3~10h |

|

水壓實驗壓力 Water Pressure Test Pressure |

0.75Mpa |

反洗用時 Time Of Backwashing |

5~10min |

|

設計溫度 Design Temperature |

0~60℃ |

過濾精度 Filtration precision |

2~5μ |

1)設定反沖洗壓力(0.5-0.8㎏/㎝2)時,不要設定過高,否則會造成過濾水質惡化,水量減少,排管異常等。

Set back flush pressure (0.5-0.8㎏/㎝2), don't set too high,or will cause deterioration of water quality, water flow reduction and abnormal exhaust pipe, etc.

2)原水進水口裝調節閥和止回閥;反沖洗進水口裝止回閥。

Install regulating valve and check valve at raw water inlet; install check valve at backflush inlet.

3)運行狀態下嚴禁往回轉齒輪處伸手或放入其他物體等。

It is strictly prohibited to reach for or put other objects into the rotary gear under the running state.

4)停機后一定要反復沖洗過濾纖維,徹底排除過濾器內部的水(使過濾纖維絲不粘有懸浮物,如沒有沖洗干凈,則會降低過濾效果)。

After the filter is shut down, it is necessary to repeatedly flush the filter fiber, and completely remove the water inside the filter (making filter fiber filaments free of suspended solids; if not, the filtering effect is reduced)

5)一個月至少進行藥劑浸泡清洗一次,用CaCLO2或NaCLO等消毒劑(CL的濃度為20ppm)注入過濾器內浸泡至少12個小時左右,進行氣、水混合沖洗清除濾材纖維絲上的藻類和微生物等物質。

Soak and clean at least once a month. Infuse disinfectant such as CaCLO2 or NaCLO (CL concentration is 20ppm) into the filter and soak for at least 12 hours. Then mix air and water to rinse and remove algae, microorganisms and other substances on the filter fiber.

6)建議三個月一次拆下所有閥門,用軟布徹底清除其內異物。

It is recommended to remove all the valves once every three months and thoroughly remove the foreign bodies with soft cloth.

7)為防止回轉齒輪生銹,需定期涂抹潤滑脂。

To prevent rotary gear from rusting, grease should be applied regularly.

|

現象malfunction |

故障原因The cause of the problem |

檢查處理 |

|

1.出水水質惡化 |

1.超過了反沖洗設定壓力Backwash set pressure exceeded 2.纖維絲發生異常The fiber filament is abnormal 3.原水進水閥門過大,進水量過大Raw water inlet valve open too large, Excessive inflow 4.原水懸浮物過高Suspended solids in raw water are too high 5.原水懸浮物直徑過小Raw water suspended solids diameter is too small |

1.準確設定反沖洗壓力Accurately set backflush pressure 2.和生產廠商聯系Contact the manufacturer 3.調整進水閥門Adjust inlet valve

4.檢查前處理設備Check the pretreatment equipment 5.調整加藥量Adjust the dosage |

|

2.處理水量減少 |

1.原水水泵發生異常The raw water pump is abnormal 2.原水進水閥開啟過小Small opening of raw water inlet valve 3.反沖洗不徹底The filter is not thoroughly being backwashed 4.異物堵塞水泵進水口Foreign matter clogs the pump inlet |

1.修理或更換Repair or replace 2.調整原水進水閥門Adjust the raw water inlet valve 3.重新進行反沖洗Redo the backwash 4.檢查水泵進水口Check the pump inlet |

|

3.氣缸運行時有異響 |

1.軸承發生故障Bearing failure 2.回轉齒輪生銹Rotary gear rusting |

1.更換軸承replace the bearing 2.除銹、涂潤滑油Remove rust and apply lubricant |

|

4.氣動閥不開啟 |

1.閥門卡住Valve sticking 2.氣動管安裝方向錯誤Pneumatic tube installed in the wrong direction 3.氣泵發生故障The air pump broke down |

1.修理或更換氣動閥Repair or replace pneumatic valves 2.重新調整氣動管方向Readjust the direction of the pneumatic tube 3.修理或更換氣泵Repair or replace the air pump |

|

5.反沖洗不徹底 |

1.反沖洗設定時間短Back flush set time is short 2.反沖洗氣量少Less backwashing airflow 3.纖維絲上有附著物繁殖Filaments with attachments to bree |

1.調整反沖洗時間Adjust the backwash time 2.檢查羅茨風機和空氣管路Check roots fan and air line 3.用氯氣消毒殺菌Sterilize with chlorine gas |

見隨機交貨資料。

See delivery documentation.

Suzhou Industrial Park Yinghan Power Auxiliary Machine Co., Ltd

聯系人:王經理

Contact Person: Manager Wang

手機:18934577129 電話:0512-62930686

Mobile phone: 18934577129 Telephone: 0512-62930686

E-mail: 18934577129 @163.com